Automation and robotics represent transformative technologies reshaping modern industries through intelligent task execution and mechanical innovation. These interconnected fields combine computer science, engineering, and artificial intelligence to create systems that operate independently or collaboratively with humans. Understanding their principles, applications, and emerging trends is essential for navigating today’s technological landscape and future career opportunities.

Good to know

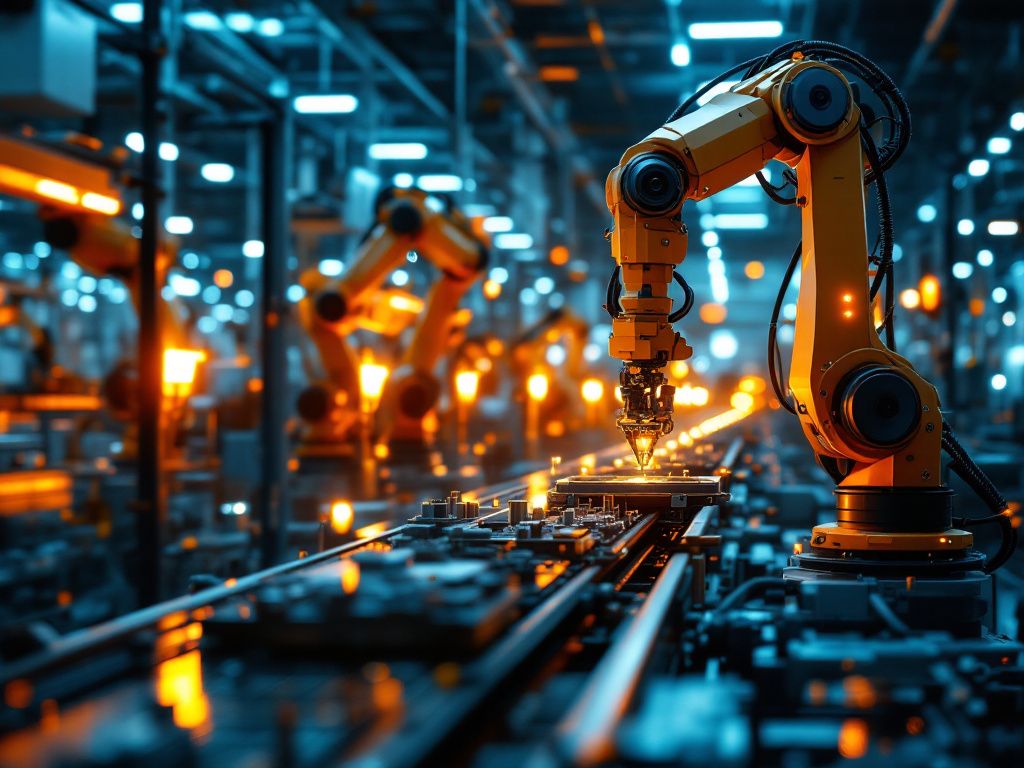

Industrial automation can increase production speed by up to 30% while simultaneously improving safety standards and reducing operational costs. Modern robotic systems excel in precision tasks like assembly, material handling, and quality inspection, delivering consistent results that enhance overall manufacturing efficiency and product quality control.

The foundation of automation and robotics

Understanding the foundation of automation and robotics requires examining two interconnected yet distinct technological domains that are reshaping modern industry. These fields represent fundamental approaches to enhancing efficiency and precision across various sectors, each with unique characteristics and applications.

Defining Automation: Technology-Driven Task Execution

Automation refers to the use of technology, software, and control systems to perform tasks automatically without direct human intervention. This broad concept encompasses a wide range of applications, from simple programmable devices to complex industrial control systems. In addition to physical or mechanical automation, many businesses now rely on digital tools that streamline operational workflows. This is where Qobra software illustrates a modern form of automation, as it enables companies to manage processes and repetitive calculations automatically, reducing manual effort and improving reliability.

A programmable thermostat exemplifies basic automation, automatically adjusting temperature based on preset schedules and environmental conditions. More sophisticated examples include automated lighting systems in buildings, computer-controlled manufacturing processes, and software automation for testing systems. Platforms similar to Qobra software are part of this evolution, showing how automation has expanded beyond robotics to include advanced computation, rules engines, and intelligent data-driven decision frameworks.

The core principle of automation focuses on creating predetermined workflows and responses that execute consistently without human oversight. These systems rely on sensors, programming logic, and control mechanisms to monitor conditions and trigger appropriate actions. Automation can exist entirely in the digital realm, such as automated email responses or data processing systems, or control physical processes through specialized equipment. The growing adoption of tools like Qobra software demonstrates how digital automation can integrate seamlessly into business environments, allowing organizations to scale processes that once required human supervision.

Understanding Robotics: The Science of Intelligent Machines

Robotics represents an interdisciplinary field that integrates computer science, engineering, and other technical disciplines to design, construct, and operate robots. Unlike general automation, robotics specifically involves creating programmable machines capable of interacting with the physical world through sensory input and mechanical action. CNC machines demonstrate this principle by precisely cutting and shaping materials based on digital instructions while adapting to real-time feedback.

The interdisciplinary nature of robotics draws from mechanical engineering for physical design, computer science for programming and control algorithms, electrical engineering for sensors and actuators, and increasingly, artificial intelligence for decision-making capabilities. Robots can operate autonomously, semi-autonomously with human oversight, or through direct human control, depending on their design and application requirements.

Core Differences and Technological Scope

While automation encompasses any technology-driven process that reduces human intervention, robotics specifically focuses on physical machines designed to perform tasks in real-world environments. Automation may involve purely software-based solutions, whereas robotics always includes hardware components designed to interact with physical objects and spaces. This distinction highlights how robotics serves as a specialized subset within the broader automation landscape.

Applications and benefits in modern industry

Modern industry has experienced a transformative shift through the strategic implementation of automation and robotics technologies. These advanced systems have revolutionized traditional manufacturing processes, delivering unprecedented levels of efficiency and precision across diverse industrial sectors.

Manufacturing Excellence Through Automation

Industrial automation has fundamentally enhanced production speed and safety in manufacturing environments. Automated production lines now operate continuously with minimal human intervention, achieving output rates that exceed traditional manual processes by 15% to 25%. These systems utilize sophisticated sensors and control mechanisms to monitor production parameters in real-time, ensuring consistent quality while reducing the risk of workplace accidents.

The implementation of automated quality control systems has proven particularly valuable in electronics manufacturing, where precision is paramount. Automated inspection systems can detect defects at microscopic levels, maintaining product standards that would be impossible to achieve through manual inspection alone.

Robotic Applications in Industrial Processes

Industrial robots have become indispensable for executing complex tasks including assembly, material handling, and precision inspection. Robotic arms perform welding operations with millimeter-level accuracy, while automated guided vehicles transport materials throughout facilities without human oversight. In the automotive industry, robots handle heavy components and execute repetitive assembly tasks, significantly reducing physical strain on human workers.

Material Handling and Logistics

Robotic systems excel in material handling applications, particularly in warehousing and distribution centers. These systems can operate continuously, processing orders and managing inventory with remarkable efficiency. Advanced robotic platforms navigate complex warehouse environments autonomously, optimizing picking routes and reducing order fulfillment times.

Quantifiable Benefits and Cost Reduction

The financial advantages of automation and robotics implementation are substantial. Manufacturing facilities report cost reductions of up to 30% through decreased labor expenses and improved resource utilization. Quality control improvements result in reduced waste and rework costs, while enhanced production consistency minimizes defect-related expenses. These systems also extend operational capacity by enabling 24/7 production cycles without compromising quality or safety standards.

Emerging trends in automation and robotics

The landscape of automation and robotics is rapidly evolving, driven by groundbreaking technological advancements that are reshaping how industries operate. These emerging trends are not only transforming traditional manufacturing processes but also expanding into new sectors, creating unprecedented opportunities for efficiency and innovation.

Artificial Intelligence Integration Revolutionizes Robotic Capabilities

The integration of artificial intelligence with robotic systems represents one of the most significant emerging trends in the field. Modern robots are becoming increasingly intelligent, capable of learning from their environment and adapting to new situations without extensive reprogramming. This AI-powered robotics technology enables machines to perform complex decision-making tasks, analyze vast amounts of data in real-time, and continuously improve their performance through machine learning algorithms.

These intelligent systems are particularly transformative in logistics operations, where robots can now optimize warehouse layouts, predict maintenance needs, and coordinate with human workers more effectively than ever before. The technology allows for dynamic route planning and inventory management that responds instantly to changing conditions.

Robotic Process Automation Expands Beyond Manufacturing

Robotic Process Automation (RPA) has emerged as a game-changing trend, extending automation capabilities far beyond traditional industrial applications. In customer service, RPA systems are handling routine inquiries, processing orders, and managing customer data with remarkable accuracy. These software-based robots can work 24/7, significantly reducing response times and improving customer satisfaction rates.

The logistics industry has embraced RPA for supply chain management, where automated systems track shipments, manage inventory levels, and coordinate deliveries across multiple platforms simultaneously. This automation reduces human error and accelerates processing times substantially.

Collaborative Robots Transform Human-Machine Interaction

The development of collaborative robots, or cobots, represents a fundamental shift toward human-robot partnerships rather than replacement scenarios. These emerging trends in robotics focus on creating machines that work alongside humans safely and efficiently, enhancing human capabilities rather than substituting them entirely. Cobots are designed with advanced sensors and safety features that allow them to operate in shared workspaces without protective barriers.

Automation and robotics in education and career development

The rapid advancement of automation and robotics technologies has created an unprecedented demand for skilled professionals, making education and training programs essential for career development in this dynamic field. As industries increasingly adopt automated systems and robotic solutions, educational institutions across the United States are responding with comprehensive programs designed to prepare students for high-tech manufacturing careers.

Academic Programs and Institutional Offerings

Ozarks Tech leads the way with its Associate of Applied Science in Automation and Robotics program, offering a 63-hour curriculum that covers electrical, mechanical, and fluid power systems. Students gain hands-on experience with programmable logic controllers (PLCs) and industrial robotics through specialized coursework. The program specifically prepares graduates for roles as automation and maintenance technicians, emphasizing practical skills development through laboratory work and industry-grade equipment training.

Similar programs are available at institutions throughout North Carolina and other states, where students can pursue applied science degrees focused on automation technology. These programs typically require students to demonstrate proficiency in both theoretical knowledge and practical application, ensuring graduates are workforce-ready upon completion.

Essential Skills Development

Modern automation and robotics education emphasizes three core competency areas. Programming skills form the foundation, with students learning to develop and modify control systems for automated manufacturing processes. Electrical systems training covers industrial networking communications and control circuitry, while mechanical systems instruction focuses on fluid power and robotic operation principles.

Career Prospects and Industry Outlook

The job outlook for automation and robotics professionals remains exceptionally strong, with the Bureau of Labor Statistics projecting continued growth in manufacturing and technology sectors. Graduates can pursue positions as robotics technicians, automation specialists, or maintenance technicians, with opportunities spanning electronics, healthcare, agriculture, and military applications. Industry-recognized credentials further enhance employment prospects, positioning graduates for advancement in the evolving landscape of Industry 4.0 manufacturing.

What to remember about automation and robotics

Automation and robotics continue to evolve rapidly, driven by artificial intelligence integration and collaborative technologies. The future promises greater human-robot collaboration, enhanced adaptability, and expanded applications across diverse industries. Educational institutions are responding with specialized programs to prepare the workforce for emerging opportunities. As these technologies mature, we can expect increased efficiency, new job categories, and continued transformation of traditional manufacturing and service sectors. Success in this field will depend on continuous learning and adaptation to technological advances.